How Much Does DTF Printing Really Cost?: Your Ultimate Guide for Apparel Sellers

So, you're diving into the exciting world of custom apparel, right? Whether you're a budding entrepreneur with a small Etsy shop or a seasoned t-shirt veteran looking for the next big thing, you've probably heard about Direct-to-Film (DTF) printing. It's super popular for a reason: incredible quality, vibrant colors, and it works on almost any fabric. But let's be real – the big question always comes down to cost. How much is this going to set me back?

Figuring out the true cost of DTF printing isn't a one-size-fits-all answer. It depends on a few key things: how much you're printing, how intricate your designs are, and the method you choose. Let's break it down so you can make the best decision for your business.

Factors That Impact Your DTF Printing Bill

Before we get into the nitty-gritty, understanding these factors will help you estimate costs more accurately:

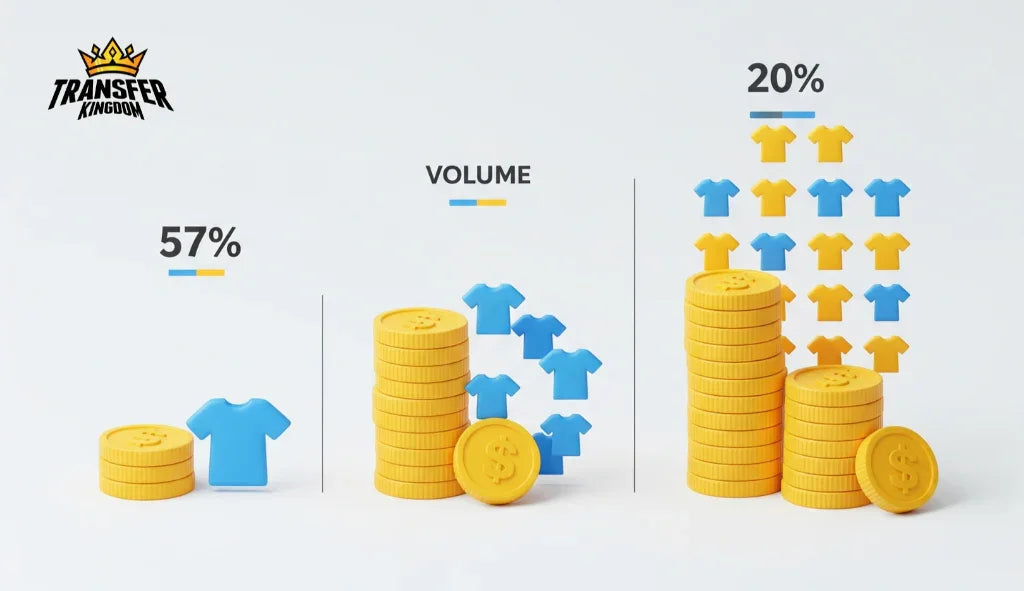

- Order Volume: This is a big one. Just like with anything, the more you buy, the cheaper it usually gets per item. A single transfer will cost more per piece than if you order a hundred.

- Design Complexity & Size: A small, simple logo will naturally cost less than a large, full-color design with tons of details. The larger your design, the more film and ink it uses, which means a higher cost.

- Production Method: Are you buying ready-to-press transfers, printing them yourself, or outsourcing the whole job? Each path has a very different cost structure.

DTF Printing Cost Breakdown: Your Options

Let's explore the most common ways to get into DTF printing and what they typically cost.

Option 1: Buying Individual Pre-Printed DTF Transfers (Ready-to-Press)

This is often the go-to for hobbyists or small businesses just starting out, or if you only need a few custom pieces. You simply order your designs, and they arrive ready for you to press onto your apparel using a heat press. It's super convenient and requires minimal upfront investment.

Pros:

- No big upfront costs: You don't need expensive equipment.

- Easy to use: Just press and go!

- Great for small runs: Perfect for testing new designs or fulfilling small orders.

- High quality: Professional printers ensure top-notch results.

Cons:

- Higher cost per transfer for very small quantities.

- Waiting time for shipping.

- Where to find them: You can get high-quality DTF transfers and blanks for your apparel projects directly from places like transferkingdom.com.

Option 2: Using DTF Gang Sheets

What's a gang sheet? Imagine a big canvas where you can arrange multiple designs – different sizes, different logos, whatever you need – to fill the space. You pay for the sheet size, not each individual design. This is an awesome way to save money if you have several designs or various sizes of the same design you need printed.

Cost Range:

- Small Gang Sheet (e.g., 22" x 24"): Around $35 to $60

- Medium Gang Sheet (e.g., 22" x 60"): Around $70 to $120

-

Large Gang Sheet (e.g., 22" x 120"): Around $100 to $150+

The cost per design on a gang sheet can be significantly lower, especially if you optimize the space well.

Pros:

- Massive cost savings when printing multiple designs or sizes.

- Optimizes material usage.

- Reduces waste.

Cons:

- Requires a bit more planning to lay out your designs efficiently.

- Where to find them: Many DTF transfer providers, including transferkingdom.com, offer gang sheet services, letting you maximize your value.

Option 3: Investing in Your Own DTF Setup

For serious businesses with consistent, high-volume needs, setting up your own DTF printing operation might be the most cost-effective long-term solution. But be warned: it's a significant investment!

Initial Investment: Expect to spend anywhere from $5,000 to $20,000+. This includes:

- DTF Printer: These can range from smaller desktop models to large industrial machines.

- Powder Shaker/Curer: Essential for applying and curing the adhesive powder.

- Heat Press: For pressing the transfers onto garments.

- Consumables: DTF ink, DTF film, adhesive powder, cleaning solutions, maintenance supplies.

Running Costs:

- Ink: Varies greatly by printer and usage, but it's a constant expense.

- Film & Powder: Also ongoing costs.

- Maintenance: DTF printers require regular cleaning and upkeep to prevent clogs and ensure quality.

- Electricity: Your machines will need power!

Pros:

- Ultimate control over production, quality, and turnaround times.

- Lowest cost per print in the long run for high volumes.

- Flexibility to print on demand.

Cons:

- High upfront investment.

- Steep learning curve for operating and maintaining the equipment.

- Requires dedicated space and proper ventilation.

- Ongoing maintenance and potential downtime for repairs.

Option 4: Outsourcing to a Full-Service DTF Print Shop

Maybe you need a large batch of custom apparel but don't want to handle the transfers yourself, or you don't have a heat press. That's where a full-service print shop comes in. They'll handle everything from printing the transfers to pressing them onto the garments and even shipping. This is ideal for bulk orders where you want a completely finished product.

Cost Range:

The cost per shirt can vary widely, from $5 to $20+ per shirt, depending on the order size, design complexity, number of print locations (front, back, sleeve), and the type of garment. Larger orders significantly reduce the per-shirt cost.

Pros:

- Completely hands-off: They do all the work.

- Professional results: Experienced printers ensure top quality.

- Great for large orders and complex jobs.

- No equipment needed on your end.

Cons:

- Higher cost per shirt than doing it yourself or buying just transfers.

- Less control over immediate turnaround times.

- Where to find them: For finished apparel ready to sell, a print shop like tkshirt.com can handle your larger custom orders from start to finish.

So, What's the "Right" DTF Cost for You?

As you can see, there's no single answer. The best DTF printing solution – and its cost – depends entirely on your specific business model, volume, and comfort level with managing production.

- Just starting or have small, infrequent orders? Buying pre-printed DTF transfers from transferkingdom.com is probably your most cost-effective and convenient choice.

- Have multiple designs or need to optimize space? DTF gang sheets are your secret weapon for savings.

- Growing rapidly with high-volume needs? An in-house DTF setup could be a worthwhile investment over time, despite the initial sticker shock.

- Need a finished product for bulk orders without the hassle? Outsourcing to a full-service print shop like tkshirt.com will save you time and labor.

Take some time to assess your current needs and future goals. By understanding these cost factors and options, you'll be well on your way to making smart decisions for your custom apparel business!

Ready to get started? Explore our high-quality DTF transfers and blanks at transferkingdom.com, or if you need full-service printing, visit tkshirt.com!